Advantages and disadvantages of COB packaged LED display screen and its development difficulties

With the continuous progress of solid-state lighting technology, COB (chip on board) packaging technology has received more and more attention. As COB light source has the characteristics of low thermal resistance, high luminous flux density, less glare, and uniform emission, it has been widely used in indoor and outdoor lighting fixtures, such as down lamp, bulb lamp, fluorescent tube, street lamp, and industrial and mining lamp.

This paper describes the advantages of COB packaging compared with traditional LED packaging, mainly from six aspects: theoretical advantages, manufacturing efficiency advantages, low thermal resistance advantages, light quality advantages, application advantages, and cost advantages, and describes the current problems of COB technology.

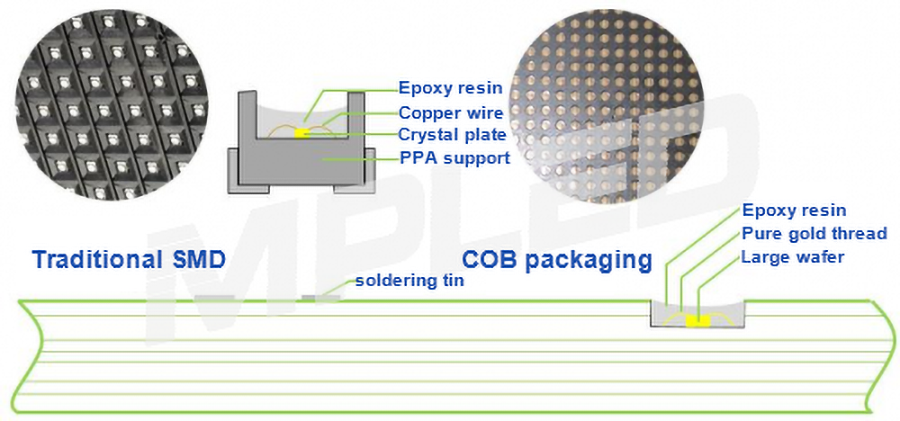

Differences between COB packaging and SMD packaging

Theoretical advantages of COB:

1. Design and development: without the diameter of a single lamp body, it can be smaller in theory;

2. Technical process: reduce the cost of the bracket, simplify the manufacturing process, reduce the thermal resistance of the chip, and achieve high-density packaging;

3. Engineering installation: From the application side, COB LED display module can provide more convenient and fast installation efficiency for the manufacturers of display application side.

4. Product characteristics:

(1) Ultra light and thin: PCB boards with thickness ranging from 0.4-1.2mm can be used according to the actual needs of customers to reduce the weight to at least 1/3 of the original traditional products, which can significantly reduce the structure, transportation and engineering costs for customers.

(2) Collision resistance and compression resistance: COB products directly encapsulate LED chips in concave lamp positions of PCB boards, and then encapsulate and solidify them with epoxy resin adhesive. The surface of the lamp points is raised into a spherical surface, which is smooth, hard, impact resistant and wear-resistant.

(3) Large angle of view: the angle of view is greater than 175 degrees, close to 180 degrees, and has a better optical diffuse color muddy light effect.

(4) Strong heat dissipation capability: COB products encapsulate the lamp on the PCB, and quickly transfer the heat of the lamp wick through the copper foil on the PCB. The copper foil thickness of PCB board has strict process requirements. With the addition of gold deposition process, it will hardly cause serious light attenuation. Therefore, there are few dead lights, greatly extending the life of LED display.

(5) Wear resistant, easy to clean: smooth and hard surface, impact resistant and wear-resistant; There is no mask, and the dust can be cleaned with water or cloth.

(6) All weather excellent characteristics: triple protection treatment is adopted, with outstanding waterproof, moisture, corrosion, dust, static electricity, oxidation and ultraviolet effects; It can meet the all-weather working conditions, and the temperature difference environment from – 30 ℃ to – 80 ℃ can still be used normally.

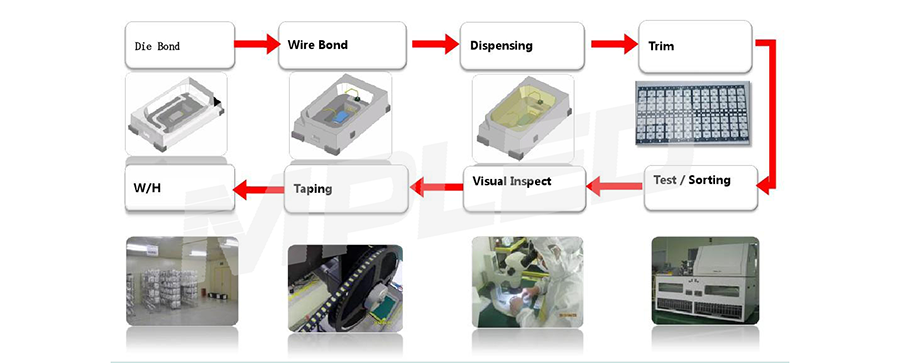

Introduction to COB Packaging Process

1. Advantages in manufacturing efficiency

The production process of COB packaging is basically the same as that of traditional SMD, and the efficiency of COB packaging is basically the same as that of SMD packaging in the process of solid solder wire. In terms of dispensing, separation, light distribution and packaging, the efficiency of COB packaging is much higher than that of SMD products. The labor and manufacturing costs of traditional SMD packaging account for about 15% of the material cost, while the labor and manufacturing costs of COB packaging account for about 10% of the material cost. With COB packaging, labor and manufacturing costs can be saved by 5%.

2. Advantages of low thermal resistance

The system thermal resistance of traditional SMD packaging applications is: chip – solid crystal adhesive – solder joint – solder paste – copper foil – insulating layer – aluminum. The thermal resistance of COB packaging system is: chip – solid crystal adhesive – aluminum. The system thermal resistance of COB package is much lower than that of traditional SMD package, which greatly improves the life of LED.

3. Light quality advantages

In traditional SMD packaging, multiple discrete devices are pasted on the PCB to form the light source components for LED applications in the form of patches. This method has the problems of spot light, glare and ghosting. The COB package is an integrated package, which is a surface light source. The perspective is large and easy to adjust, reducing the loss of light refraction.

4. Application advantages

COB light source eliminates the process of mounting and reflow soldering at the application end, greatly reduces the production and manufacturing process at the application end, and saves the corresponding equipment. The cost of production and manufacturing equipment is lower, and the production efficiency is higher.

5. Cost advantages

With COB light source, the cost of the whole lamp 1600lm scheme can be reduced by 24.44%, the cost of the whole lamp 1800lm scheme can be reduced by 29%, and the cost of the whole lamp 2000lm scheme can be reduced by 32.37%

Using COB light source has five advantages over using traditional SMD package light source, which has great advantages in light source production efficiency, thermal resistance, light quality, application and cost. The comprehensive cost can be reduced by about 25%, and the device is simple and convenient to use, and the process is simple.

Current COB technical challenges:

At present, COB’s industry accumulation and process details need to be improved, and it also faces some technical problems.

1. The first pass rate of packaging is low, the contrast is low, and the maintenance cost is high;

2. Its color rendering uniformity is far less than that of the display screen behind SMD chip with light and color separation.

3. The existing COB packaging still uses the formal chip, which requires the solid crystal and wire bonding process. Therefore, there are many problems in the wire bonding process, and the process difficulty is inversely proportional to the pad area.

4. Manufacturing cost: due to the high defective rate, the manufacturing cost is far higher than the SMD small spacing.

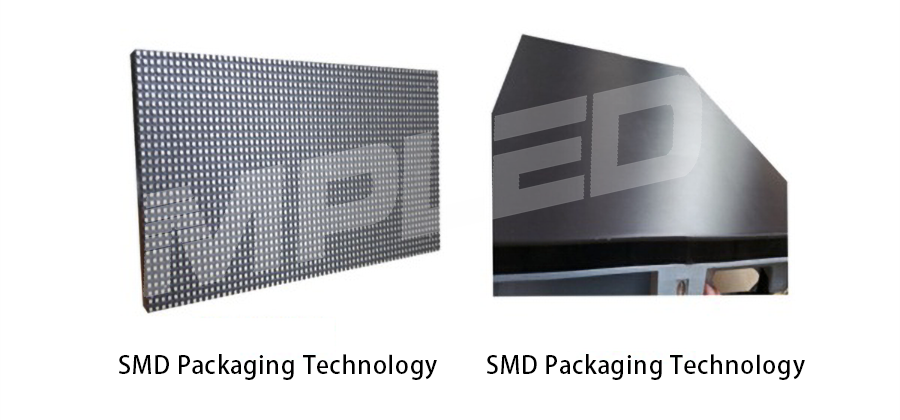

Based on the above reasons, although the current COB technology has made some breakthroughs in the display field, it does not mean that the SMD technology has completely withdrawn from the decline. In the field where the point spacing is more than 1.0mm, the SMD packaging technology, with its mature and stable product performance, extensive market practice and perfect installation and maintenance guarantee system, is still the leading role, and is also the most suitable selection direction for users and the market.

With the gradual improvement of COB product technology and the further evolution of market demand, the large-scale application of COB packaging technology will reflect its technical advantages and value in the range of 0.5mm~1.0mm. To borrow a word from the industry, “COB packaging is tailored for 1.0mm and below”.

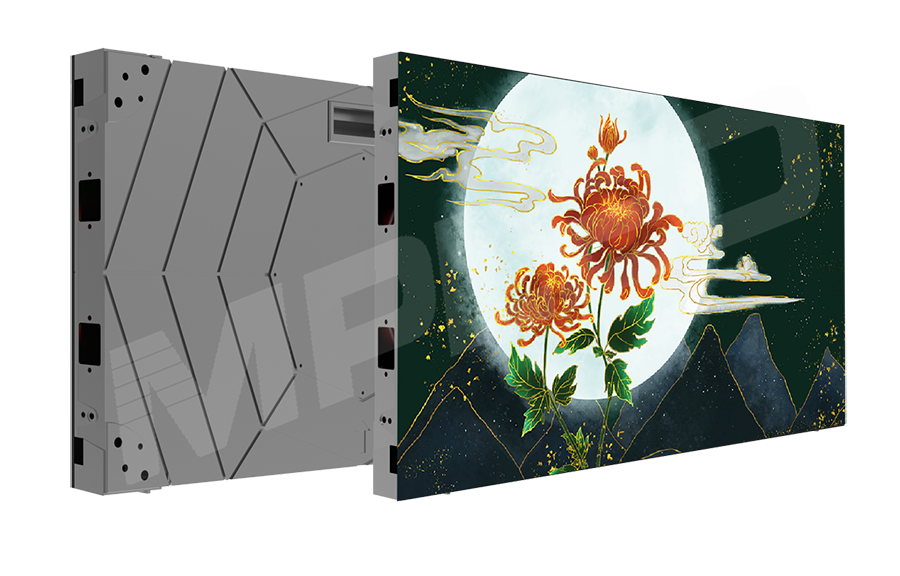

MPLED can provide you with LED display of COB packaging process, and our ST Pro series products can provide such solutions. The LED display screen completed by cob packaging process has smaller spacing, clearer and more delicate display image. The light-emitting chip is directly packaged on the PCB board, and the heat is directly dispersed through the board. The thermal resistance value is small, and the heat dissipation is stronger. Surface light emits light. Better appearance.

ST Pro series

Post time: Nov-30-2022